Programmable Logic Controllers (PLCs) are essential for modern industrial automation, offering improved efficiency, accuracy, and reliability. This quick guide from RAM Automations explains the basics and steps to implement a PLC system in your operation.

What is a PLC?

A PLC is a specialized industrial computer designed to control machinery and processes in harsh environments. Unlike standard PCs, PLCs are durable, fast, and built for real-time control.

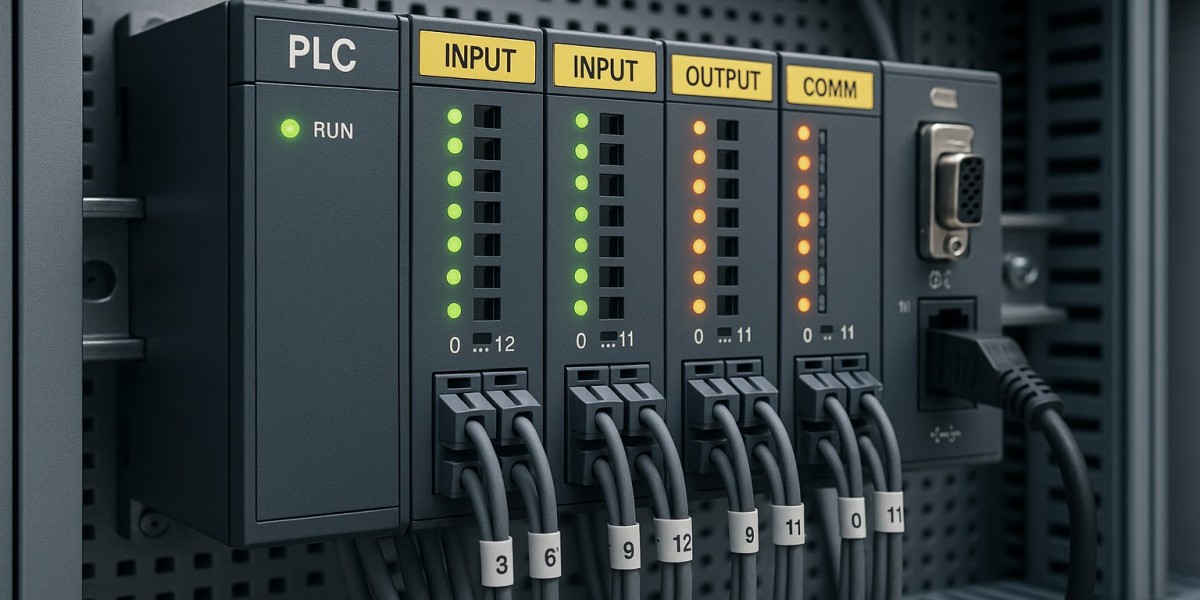

Core Components of a PLC System:

- CPU: Executes the control program.

- I/O Modules: Interface with sensors and actuators.

- Power Supply: Powers the PLC and components.

- Programming Device: Used to write and upload logic.

- Communication Ports: Connects to HMI, SCADA, etc.

Implementation Steps:

- Define Objectives: Identify the process to automate.

- Design the Program: Use ladder logic to build the control sequence.

- Test Before Deployment: Simulate and debug the logic.

- Install Hardware: Mount PLC, connect inputs/outputs, and power on.

- Monitor & Maintain: Use SCADA/HMI for real-time tracking and update the system as needed.

Conclusion

A PLC system boosts automation, reduces manual errors, and enhances productivity. RAM Automations offers expert guidance, reliable products, and complete support for your automation needs.

? Visit ramautomations.com to get started.